Event Held to Mark the Achievement of Reaching a Total of

300 Million Units of Waste Appliances Collected for Recycling:

“Opinion Sharing Meeting by Recycling Plants”

In July 2023, the 23rd year since the enforcement of the Home Appliance Recycling Law in 2001, the total number of waste home appliance units collected for recycling reached 300 million. To commemorate this achievement, an opinion sharing meeting by recycling plants was held at Ritsumeikan University, Osaka Ibaraki Campus.

The meeting started with an explanatory presentation on home appliance recycling by Professor Nakamura of Ritsumeikan University, College of Business Administration, a researcher in the relations between recycling and business. Following the presentation, members from 9 recycling plants across Japan shared their views and Ritsumeikan University students also shared their opinions and comments.

Explanatory presentation on “Current Status and Achievements of Home Appliance Recycling” by Professor Nakamura

Enforcement of the Home Appliance Recycling Law

Since the period of high economic growth, waste-related issues such as “lack of landfills,” “environmental pollution,” “improper management,” and “illegal dumping” had become serious. Eventually, movements to develop systems and legislation relating to waste and recycling began, and in 2001 the Home Appliance Recycling Law was enforced.

“Home Appliance Recycling” contributes to a circular society

Collection of waste home appliances (four specified kinds) started in 2001 with the enforcement of the Home Appliance Recycling Law, and in July 2023, the 23rd year from enforcement, the total number of units collected reached 300 million. By calculation this means that about 10 units of waste appliances were processed per household, and we can see that the system is working effectively even from a global perspective.

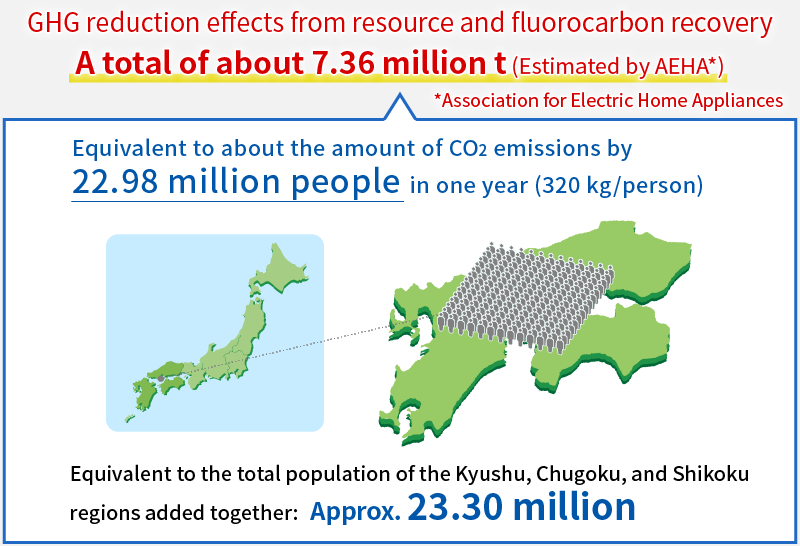

CO2 emission reduction effects (annual) from home appliance recycling

GHG reduction effects from resource and fluorocarbon recovery amount to about 7.36 million t, which is equivalent to about the amount of CO2 emissions by 23.30 million people, the total population of the Kyushu, Chugoku, and Shikoku regions added together.

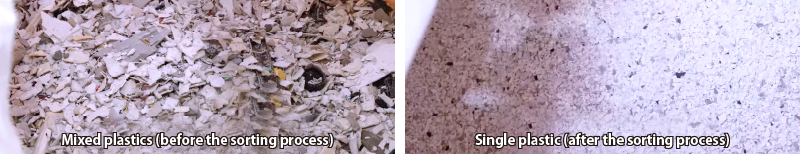

Presentation and sharing of views by recycling plants

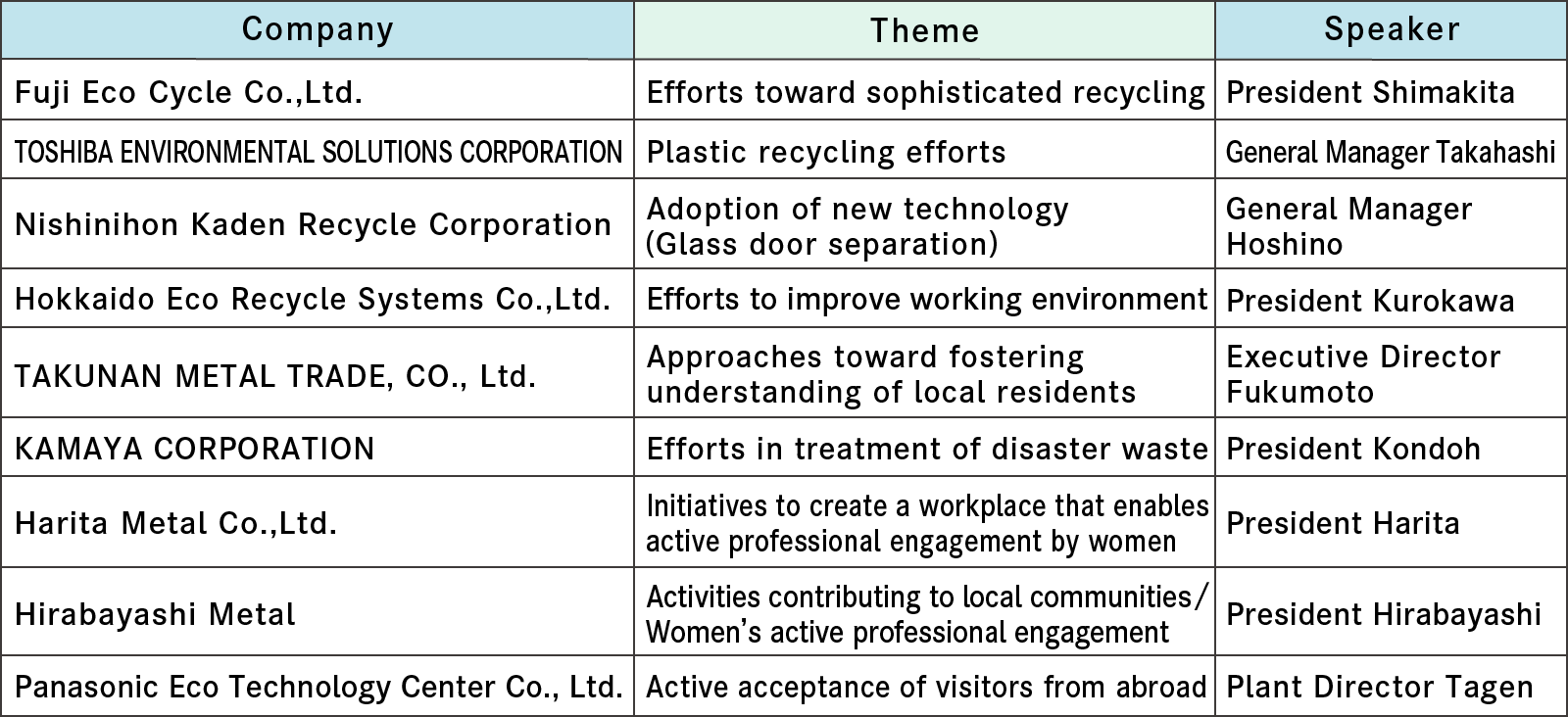

Representatives from recycling plants gave theme-based presentations and introduced examples of their efforts in home appliance recycling; various creative ideas and activities implemented at recycling plants were presented.

Fuji Eco Cycle Co.,Ltd.: “Efforts toward sophisticated recycling”

Fuji Eco Cycle is increasing the proportion of single materials to achieve sophisticated recycling. Introducing a wet sorter using water in the process of plastic recycling has made it possible to sort mixed plastics into white and colored PP for separate recovery. In addition, with shell cutter equipment devised by Fuji Eco Cycle itself, compressors of refrigerators and air conditioners are separated into specific materials such as copper wires and iron cores.

TOSHIBA ENVIRONMENTAL SOLUTIONS CORPORATION: “Plastic recycling efforts”

Although the recycling rate of the four specified kinds of home appliances was about 66% when the Home Appliance Recycling Law was enforced, currently it has improved to about 87%. Toshiba Environmental Solutions has greatly contributed to the achievement of the 20% improvement through plastic recycling. One of its efforts is the introduction of a sorting system for mixed plastics, where bulks of waste appliances that cannot be dismantled/separated with a large-scale shredder are entirely crushed, metals are removed from the crushed pieces, and the remaining mixed plastics are separated by means of various sorting techniques.

Nishinihon Kaden Recycle Corporation: “Adoption of new technology (Glass door separation)”

Being the only recycling plant in Japan that treats the four specified types of waste home appliances of both Groups A and B, Nishinihon Kaden Recycle receives many different types of waste appliances of various manufacturers. Here, the latest “laser-stripping technology” has been introduced to separate the glass from the doors of glass-door refrigerators, which is a refrigerator type recently increasing in the market. Aiming for “faster” and “neater” separation rather than simply separating materials, Nishinihon Kaden Recycle continues to work on demonstrations and verifications in collaboration with manufacturers.

Hokkaido Eco Recycle Systems Co.,Ltd.: “Efforts to improve working environments”

Hokkaido Eco Recycle Systems gave a presentation on its efforts to create better working environments. Such efforts came from circumstances where exceptionally scorching heat in Hokkaido led to poor physical conditions of workers and lack of air conditioning, as well as having to work in heavy snow due to recent extreme weather. The presentation also included issues and countermeasures unique to home appliance recycling plants located in a cold region where the temperature falls below freezing; Hokkaido Eco Recycle Systems gave examples such as how it manages the appliances to keep the liquid inside the units from freezing and how it is careful with gases that liquefy in low temperature.

TAKUNAN METAL TRADE, CO., Ltd.: “Approaches toward fostering understanding of local residents”

Takunan Metal Trade started its business through reconstruction efforts utilizing iron resources that were used in the war and is now a company that actively supports Okinawa prefecture’s circular society. It is taking various approaches to gain understanding from local residents, by not only conducting clean-up activities inside the industrial park as contribution to the community, but also by taking part in illegal dumping patrols hosted by the prefecture of Okinawa. In addition, Takunan Metal Trade contributes to encouraging the region’s recycling in various ways, such as accepting waste appliances from the remote islands of Okinawa or diverting vehicle glass away from landfills which conventionally was the only method for treatment and using it as an ingredient for “Ryukyu glass,” a traditional craft of Okinawa.

KAMAYA CORPORATION: “Efforts in treatment of disaster waste”

Kamaya has an open culture where employees freely share their ideas, and opinions are proactively accepted.

In the presentation, Kamaya gave some examples of how it deals with waste appliances caused by the Great East Japan Earthquake in 2011 (disaster waste) as well as the challenges it is facing. After the disaster, there were numerous difficulties and confusion which Kamaya needed to address: items other than the four specified kinds of home appliances were mixed in the collection; appliances were handled roughly with heavy machinery; appliances were covered with dirt or crushed due to damages from the tsunami; etc. It took nearly a year until waste appliances were properly brought into the plant. In addition, home appliances that were radioactively contaminated by the Fukushima nuclear accident were brought into designated collection points, which led Kamaya to set its own dosimetry criteria and execute recycling with due consideration to the safety of its employees. Recently, with the increase in areas where evacuation orders were lifted, waste appliances from such areas are being brought in; treatment of disaster waste is still ongoing today.

Harita Metal Co.,Ltd.: “Initiatives to create a workplace that enables active professional engagement by women”

Aiming to create a comfortable workplace that enables active professional engagement by women, Harita Metal has implemented a workstyle reform. The percentage of employees who take paid leaves is 99.5%, and a system is in place so that male employees can take paternity leaves without much difficulty. At Harita Metal, female employees who energize the workplace are called “Risajo (i.e., ‘women engaged in recycling’),” and the company strives to actively employ women as well as create comfortable workplaces. To boost the impression of the recycling business, Harita Metal is working to become acknowledged as a comfortable and attractive workplace for anyone and everyone; using a smart watch for health management is one example. Harita Metal has also been visited by Japan’s Prime Minister Kishida who came to see and know about the initiatives for creating a comfortable workplace.

Further, two “Risajos” Ms. Maeda and Ms. Yamazaki shared their views about the company. Ms. Maeda explained that employees are allowed to have a second job outside the company and therefore can balance their careers and private lives, and also highlighted the good relationship with coworkers who help each other when there are problems. Ms. Yamazaki spoke about other features of the company, such as the environment where paid leaves can be taken by the hour, which is helpful for employees raising children, as well as efforts to make up for the differences in physical strength between males and females by introducing equipment and providing support.

Hirabayashi Metal: “Activities contributing to local communities / Women’s active professional engagement”

Hirabayashi Metal actively employs women, and about 25 of the 100 or so female employees in the entire corporation work at the home appliance recycling lines. Employment of women at Hirabayashi Metal started when its former president was the vice chairperson of the Softball Association in 2005 and offered to hire members who played in the National Sports Festival. The women’s softball team remained in Hirabayashi Metal even after the Festival, and today former members of the team as well as active players are working as employees.

“ECOBIN,” a division in Hirabayashi Metal that handles small electric appliances, is another workplace where women are actively engaged in. They work on activities to raise awareness of proper recycling, and thanks to their attentive and thorough work the city of Okayama boasts a high recycling rate of general waste. Additionally, in the project of collecting gold to be used as material for the medals for the Tokyo Olympic Games, the city of Okayama achieved excellent results by collecting the second largest volume of gold, following Tokyo.

Two female employees of Hirabayashi Metal also spoke about their company. Ms. Hanafusa, a member of the Circular Economy Promotion Department, explained how her job is fulfilling and that she works with enthusiasm under her motto: “show gratitude to the planet by recycling.” Ms. Okazaki is an operator of equipment that sorts plastics derived from home appliances. She is also engaged in conducting “safety patrols” as a member of “Kirari-kai,” an internal group consisting mainly of female employees, to improve safety and hygienic aspects for women and to create a workplace comfortable for all genders and ages.

Panasonic Eco Technology Center Co., Ltd.: “Active acceptance of visitors from abroad”

Panasonic Eco Technology Center is a recycling plant that was built with a view to accepting visitors for plant tours. As a live material for environmental education for the generations who will lead the future, it welcomes Japanese and international visitors of all ages, and people from over 136 countries/regions have visited the plant so far. As for home appliance recycling, Panasonic Eco Technology Center executes material-specific sorting and recovery to achieve high-efficiency/high-purity resource recovery through the flow of “Producing,” “Using,” “Returning,” and “Utilizing.” It also works on various technical developments to achieve “zero emissions.”

Lastly Plant Director Tagen expressed his thoughts on home appliance recycling: “Waste home appliances have accumulated dust over the years of usage. All employees at Panasonic Eco Technology Center handle these dust-covered waste appliances sincerely with pride as “recyclists,” and will strive to achieve further resource recycling and zero emissions.”

Comments from Ritsumeikan University students

After the presentations by the recycling plants, Ritsumeikan University students shared their views. Here are some of them:

I was able to learn about home appliance recycling efforts that are in line with regional characteristics.

In addition, although I had imagined that dismantling work using machines were done mainly by men, the presentations changed my impression. I feel that the expansion of initiatives regarding the workstyles of women, such as those implemented at Hirabayashi Metal and Harita Metal, as well as adopting women’s opinions would lead to a more enthusiastic environment for the workplace.

I was surprised to know that glass doors can be separated with laser. Also, I think the efforts by recycling plants to work with manufacturers and develop easy-to-separate home appliances is something very positive to achieve a circular society.

I never knew that there were “disaster home appliances” until Kamaya’s presentation on the separation treatments of disaster appliances. I was touched by the initiatives of treating disaster appliances that are being implemented for the future.

We hear the word “recycling” in our everyday lives. Through Toshiba Environmental Solutions’ presentation on plastic sorting and Nishinihon Kaden Recycle’s video of the laser stripping, I learned that recycling is done with various latest technologies. I hope even more precise and efficient recycling continues with further development of technology.

Japanese

Japanese